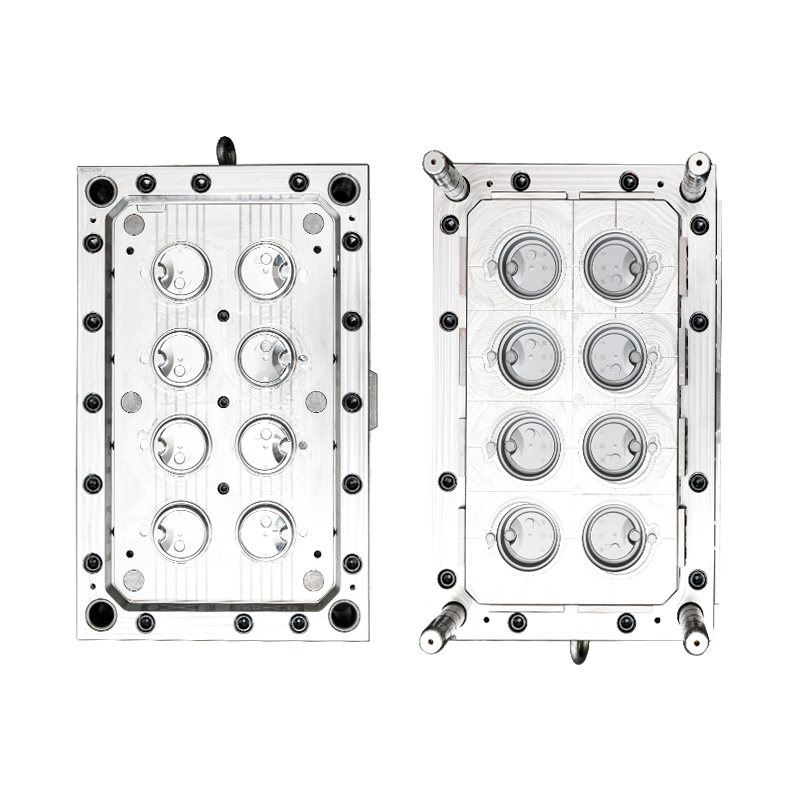

Cup molds are specialized tools designed to shape and form cups using different manufacturing techniques. These molds are crafted with precision and often customized according to the specific requirements of the cup being produced. They can be made from various materials, including metals like steel or aluminum, and are created using techniques such as CNC machining, forging, or casting.

Applications in Mass Production

In the realm of mass production, cup molds are predominantly used in industries like plastic manufacturing. Plastic injection molding involves the use of cup molds to create a multitude of plastic cups rapidly and efficiently. These molds, typically made of durable materials to withstand high pressures and temperatures, are crucial in ensuring consistent and precise cup production on a large scale.

The design intricacies of cup molds in mass production are paramount. They dictate the size, shape, texture, and even branding features of the cups. Modern cup mold technologies incorporate advanced techniques such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to create highly detailed and accurate molds, resulting in standardized and flawless cups.

Artisanal and Craft-Based Applications

In contrast, cup molds play a distinctive role in smaller-scale operations or artisanal settings. Craftsmen and artisans often use molds to shape cups from materials like ceramics, glass, or even handmade paper. These molds, handcrafted or customized for specific designs, enable artisans to produce unique and customized cups, showcasing individual creativity and craftsmanship.

The versatility of cup molds in artisanal environments allows for experimentation with shapes, sizes, and textures. Artists can create one-of-a-kind cups, incorporating intricate details and artistic elements, adding a touch of uniqueness to each piece. The molds act as a foundational tool, guiding the shaping process while leaving room for artistic expression and customization.

Advancements and Technological Innovations

Technological advancements continuously impact the landscape of cup mold manufacturing and utilization. Innovations in materials science have led to the development of more durable and heat-resistant mold materials, enhancing their longevity and efficiency in the production process.

the integration of automation and robotics in mass production facilities has revolutionized the efficiency and speed of cup production using molds. Automated systems, combined with advanced mold design and precision engineering, have significantly increased production rates while maintaining high-quality standards.

Environmental Considerations and Sustainability

In recent years, there has been a growing focus on sustainability and eco-friendliness in cup manufacturing. This shift has prompted the development of biodegradable materials and innovative manufacturing processes. Some cup molds are designed for creating environmentally friendly cups using materials such as bioplastics or recycled materials, aligning with the global drive towards sustainability.

中文简体

中文简体 Español

Español русский

русский Français

Français Português

Português عربى

عربى