IML technology has emerged as a game-changer in the packaging industry. It involves placing labels inside the mold before the plastic is injected, resulting in a seamless and durable bond between the label and the cup. The 8CAV IML cup mold leverages this technology to produce cups with vibrant, full-color designs that are not only eye-catching but also scratch-resistant and long-lasting. This ensures that the final product not only serves its functional purpose but also stands out on the shelf, catching the consumer's eye.

Unmatched Production Efficiency

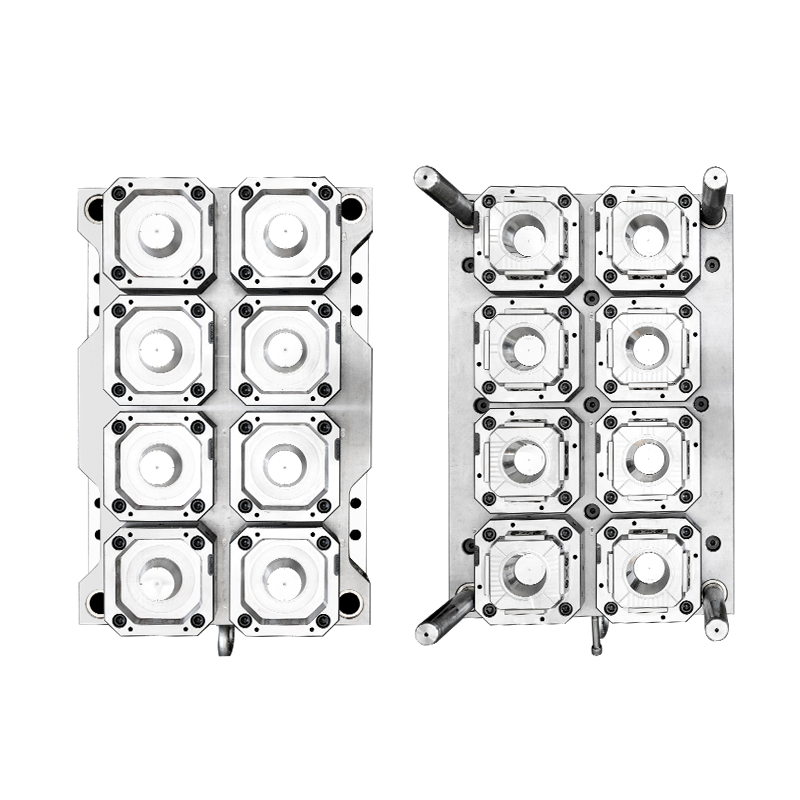

One of the most striking features of the 8CAV IML cup mold is its eight-cavity design. This means that for every cycle of the molding process, eight cups are produced simultaneously. This dramatic increase in production efficiency is a game-changer for cup manufacturers, as it significantly reduces manufacturing time, labor costs, and energy consumption. With the 8CAV IML cup mold, manufacturers can meet high demand without compromising on quality or delivery speed.

Consistency and Precision

Consistency is key in the packaging industry, where consumer expectations demand uniformity in size, shape, and labeling. The 8CAV IML cup mold excels in delivering this level of precision. With each cycle, the mold produces eight identical cups, ensuring uniformity and adherence to the highest quality standards. This level of precision is not only crucial for branding and presentation but also for maintaining the integrity of the packaged contents.

Endless Design Possibilities

The versatility of the 8CAV IML cup mold extends to cup design. With IML capabilities, manufacturers have the freedom to create intricate and eye-catching designs for their cups. Whether it's a bold brand logo, a detailed illustration, or a compelling promotional message, IML technology allows for endless design possibilities. This versatility enables manufacturers to cater to a wide range of industries and consumer preferences.

Sustainability and Reduced Waste

Sustainability is a growing concern in packaging, and the 8CAV IML cup mold contributes to eco-friendly practices. The IML process minimizes label waste, as labels are precisely placed within the mold. Additionally, the mold's efficiency and longevity reduce the need for frequent replacements, which in turn reduces waste in the production cycle. By choosing the 8CAV IML cup mold, manufacturers align with sustainable packaging practices, which are increasingly important to consumers.

The 8CAV IML cup mold represents a significant advancement in the world of packaging and container manufacturing. Its integration of In-Mold Labeling technology, coupled with its eight-cavity design, ensures unparalleled efficiency, precision, and design flexibility. As consumer demand for visually appealing and sustainable packaging solutions continues to rise, the 8CAV IML cup mold stands as a beacon of innovation. It offers a solution that not only enhances production efficiency but also creates packaging that meets the ever-evolving expectations of consumers and the demands of a competitive market. In a world where packaging is not just about protection but also about making a statement, the 8CAV IML cup mold has set a new standard for excellence.

中文简体

中文简体 Español

Español русский

русский Français

Français Português

Português عربى

عربى