IML: A Game-Changer in Cup Production

In-Mold Labeling (IML) is a revolutionary technique that integrates label application directly into the molding process. This means that labels are placed inside the mold before the plastic is injected, resulting in a seamless and durable bond between the label and the cup. The 8CAV IML cup mold takes full advantage of this technology, allowing manufacturers to produce cups with intricate, full-color designs that are scratch-resistant and long-lasting.

Unparalleled Production Efficiency

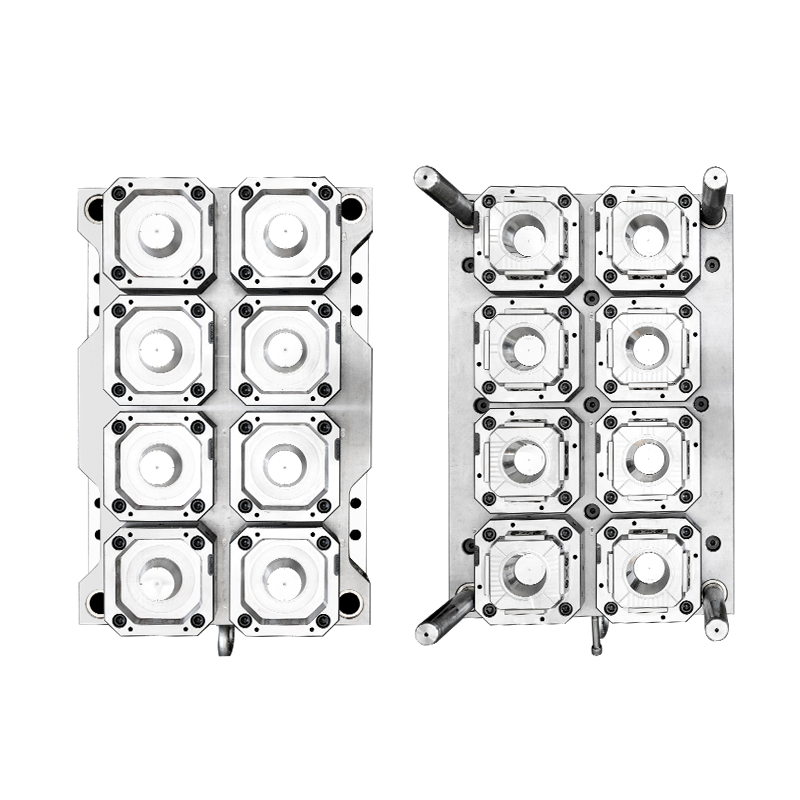

One of the standout features of the 8CAV IML cup mold is its eight-cavity design. This means that for every cycle of the molding process, eight cups are produced simultaneously. This dramatic increase in output efficiency is a game-changer for cup manufacturers, as it significantly reduces production time, labor costs, and energy consumption. With the 8CAV IML cup mold, manufacturers can meet high demand without compromising on quality or delivery speed.

Consistency and Precision

Consistency is vital in cup production, especially when dealing with large volumes. The 8CAV IML cup mold ensures that every cup produced is identical in size, shape, and labeling. This level of precision is crucial for brand consistency and customer satisfaction. Whether it's a set of promotional cups for a major event or a large-scale production run for a popular beverage, the 8CAV IML cup mold guarantees a uniform and high-quality output.

Versatility in Cup Design

The versatility of the 8CAV IML cup mold extends to cup design. With IML capabilities, manufacturers have the freedom to create intricate and eye-catching designs for their cups. The mold can accommodate a wide range of label sizes and shapes, enabling unique branding opportunities and the creation of custom-designed cups. Whether it's a vibrant, full-color image or a subtle and elegant logo, IML technology allows for endless design possibilities.

Reduced Environmental Impact

Sustainability is a top priority in today's manufacturing landscape. The 8CAV IML cup mold aligns with these goals by reducing material waste. The IML process minimizes label waste, as labels are precisely placed within the mold. Additionally, the mold's efficiency and longevity reduce the need for frequent replacements, further reducing waste in the production cycle. By choosing the 8CAV IML cup mold, manufacturers contribute to a more sustainable and eco-friendly packaging industry.

The 8CAV IML cup mold represents a transformative step forward in the world of cup production. Its integration of In-Mold Labeling technology, coupled with its eight-cavity design, ensures unparalleled efficiency, precision, and versatility. Manufacturers can now produce cups that not only meet the highest quality standards but also feature stunning and durable designs. As consumer demand for innovative and eco-friendly packaging continues to rise, the 8CAV IML cup mold is at the forefront of meeting these expectations, making it a pivotal tool in the packaging industry's journey toward excellence and sustainability.

中文简体

中文简体 Español

Español русский

русский Français

Français Português

Português عربى

عربى