Thin-walled box packaging molds are crafted with precision and expertise. They are engineered to produce boxes with thin yet resilient walls, optimizing material usage without compromising structural integrity. The process involves meticulous design considerations, including material selection, mold geometry, and manufacturing techniques, to ensure the final product meets stringent quality standards.

One of the primary advantages of utilizing thin-walled box packaging molds is their ability to reduce material consumption significantly. By employing thinner walls without sacrificing strength, these molds contribute to sustainability efforts by minimizing raw material usage. This not only lowers production costs but also lessens environmental impact, aligning with the growing demand for eco-friendly packaging solutions.

the lightweight nature of boxes manufactured through these molds presents logistical benefits. Reduced weight translates to lower shipping costs, contributing to a more economical supply chain. Additionally, lighter packaging can lead to decreased transportation emissions, further supporting environmentally conscious practices in the industry.

Beyond their practical advantages, thin-walled box packaging molds offer versatility in design. Manufacturers can customize box dimensions, shapes, and surface finishes to meet specific branding requirements. Whether it's for food, electronics, cosmetics, or various consumer goods, these molds enable the creation of packaging that not only safeguards products but also captivates consumers' attention on store shelves.

the precision of thin-walled box packaging molds ensures consistency in production. This uniformity is crucial in maintaining brand recognition and consumer trust. With accurately replicated packaging, companies can establish a cohesive brand identity and reinforce their product's perceived value among consumers.

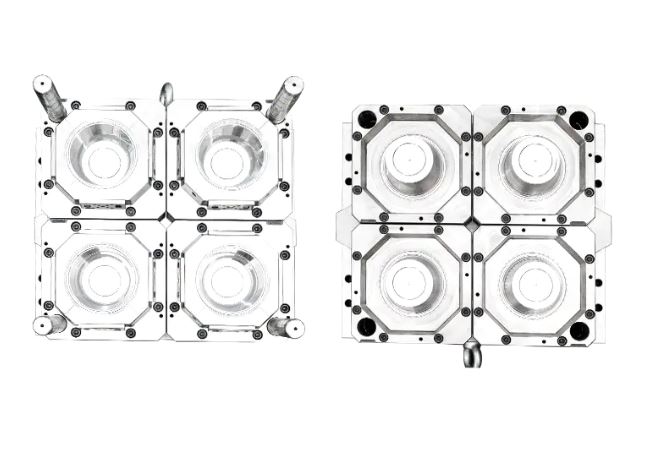

The utilization of advanced technologies in the development of these molds continues to revolutionize the packaging industry. Innovations such as multi-cavity molds, rapid prototyping, and computer-aided design (CAD) allow for faster production cycles and increased design complexity. This not only accelerates time-to-market but also facilitates the realization of intricate and unique packaging designs.

中文简体

中文简体 Español

Español русский

русский Français

Français Português

Português عربى

عربى